Introduction

Looking for cost-effective packaging that still offers good print quality? Duplex paper, also known as grey back duplex board, could be the solution you need. This article explains what duplex paper is, its features, common applications, and how to choose the right type for your packaging needs.

What Is Duplex Paper?

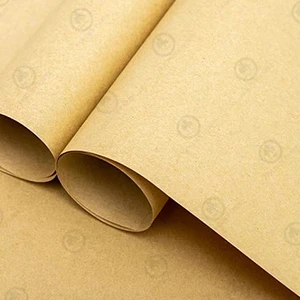

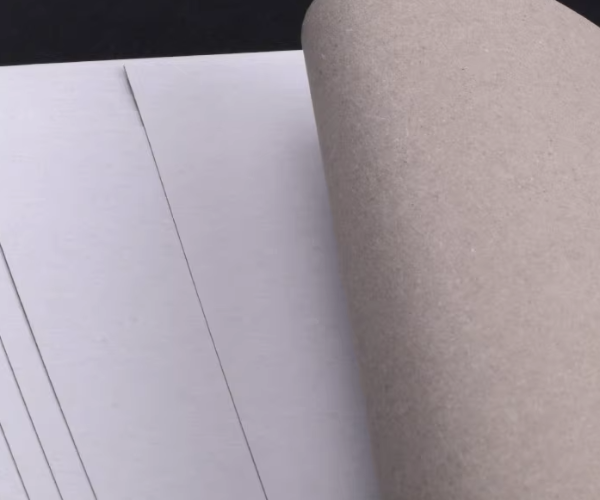

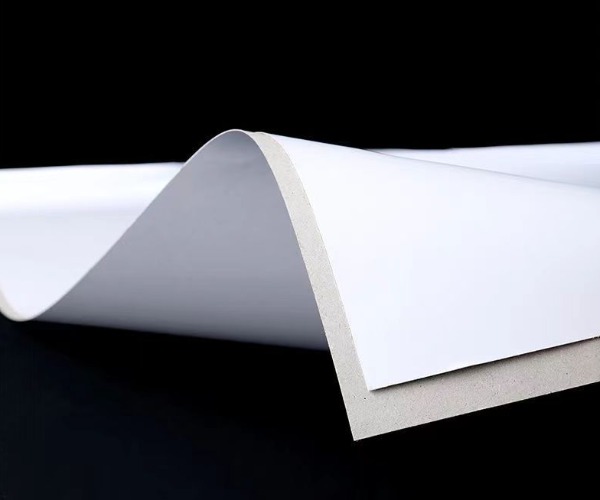

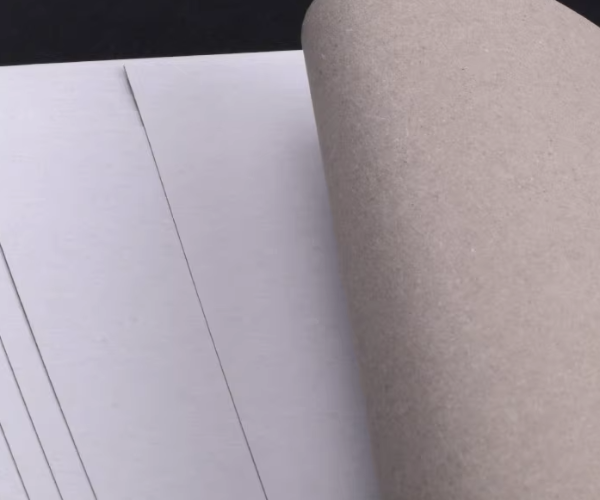

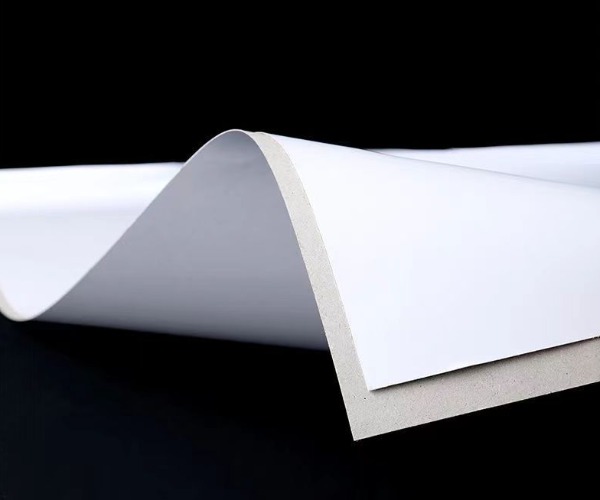

Duplex paper (or duplex board) is a type of recyclable paperboard with a double-layer structure. One side is coated white, ideal for color printing. The other side is usually grey, made from recycled pulp. This kind of board is commonly referred to as grey back duplex board, though white back options also exist.

Unlike fully coated paperboards, duplex paper has a lower gloss finish but still provides decent print clarity and color reproduction. It offers a strong balance between cost and performance, making it one of the most affordable and practical packaging materials for mid-range products.

Key Benefits of Duplex Paper

Stable and Rigid Structure

Duplex board is pressed from multiple layers of pulp, which gives it excellent stiffness and fold resistance. It holds shape well, making it suitable for forming into cartons or boxes of various structures.

Good Printability

The white surface of duplex paper is coated to enhance ink absorption, allowing for clear text, sharp images, and accurate color display—perfect for showcasing product branding and visual design.

Cost-Effective

Made primarily from recycled fibers, duplex board is significantly cheaper than virgin pulp boards like ivory board or SBS. It's a smart choice for budget-conscious packaging projects.

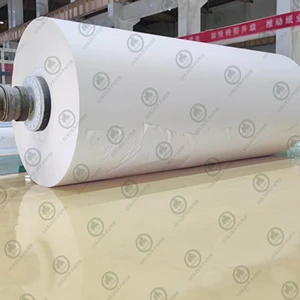

Wide Range of Thickness Options

Duplex paper is available in various grammages. At Golden Paper, we supply duplex board from 230gsm to 450gsm, offering flexibility for different packaging strength requirements.

Common Applications of Duplex Paper

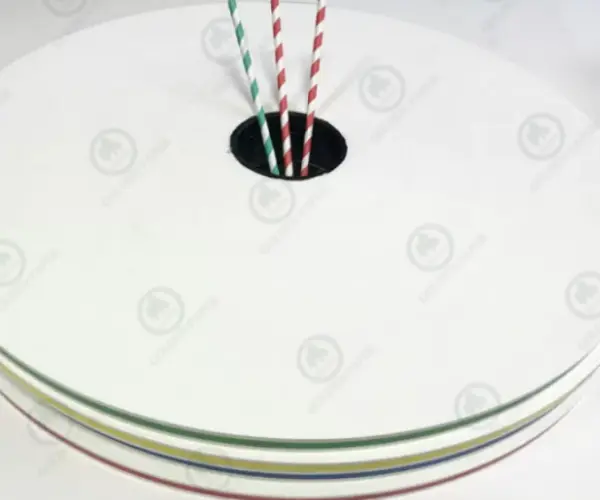

Product Packaging Boxes

Duplex board is widely used to make retail packaging boxes for products such as pharmaceuticals, electronics, stationery, toys, and processed food (note: not suitable for direct food contact). Its smooth printing surface and structural strength make it ideal for presenting products attractively.

Book Covers and Office File Holders

Because of its rigidity and durability, duplex paper is often used for book covers, file folders, and document holders that need protective outer packaging.

How to Choose the Right Duplex Paper

Here are some expert tips to help you pick the best duplex board for your product:

Match GSM to Product Weight

Lightweight items may only need 250–350gsm, while heavier products like electronics may require 400gsm or above.

Request Samples

Always ask for samples to test stiffness, fold strength, and surface quality—especially for foldable packaging.

Evaluate Print Surface

High grams duplex board provides better print contrast and image sharpness. Conduct test prints to check ink absorption and color fidelity.

Inspect the Grey Back Quality

Since duplex paper uses recycled pulp, check for tight pressing and low impurity levels on the grey side. Poor-quality grey back can reduce box strength and visual appeal.

Choose a Reliable Supplier

A stable supply chain ensures consistent quality. At Golden Paper, we've specialized in duplex paper production for over 20 years and provide fast delivery with customizable options.

Conclusion

Duplex paper is a practical, budget-friendly option for packaging across many industries. If you're looking for a trusted duplex board supplier, contact Golden Paper today. We offer a wide range of weights and sizes, custom solutions, and dependable quality to support your packaging needs.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id